Types of gears are considered one of the most important components in the industry and are used in many different applications such as engines, pumps, heavy equipment, and more. Gears are available in different types to meet the requirements of different applications in various industrial fields. In this article, we will learn about the best types of gears and how to find them with Al Andalos company.

Types of Gears:

There are several types of gears, each with its own advantages, including:

Helical gears are one of the best types of gears. These gears provide high capacity for bearing high loads and operate quietly without vibrations.

They are also characterized by precision, durability, and high efficiency.

Worm gears are also used in industry and are characterized by their ability to bear heavy loads, provide high efficiency, and operate quietly.

They are also used in applications that require the distribution of motion at a 90-degree angle.

Bevel gears are also used in the industry and are characterized by their ability to bear high loads and work in harsh environments.

They are typically used in automotive, aerospace, marine, and heavy equipment applications.

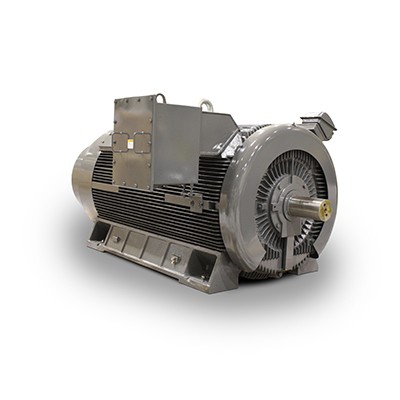

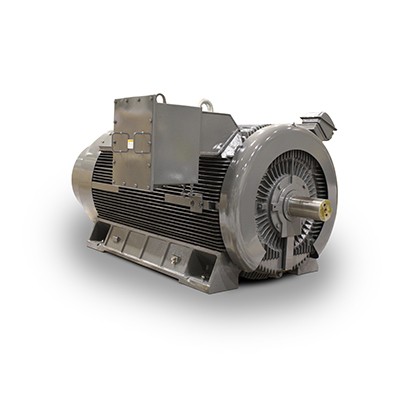

i-Mak company offers a wide range of industrial gears in different sizes and types that meet the requirements of many different applications.

You can obtain i-Mak gear products through Al Andalos company.

Gear sizes

There are many different sizes and types of gears, which are determined based on several factors such as size, shape, and type.

Among these sizes are:

Pitch diameter

This is the most commonly used measurement for determining gear size, and it is measured in length units such as millimeters or inches.

Number of teeth

This determines the amount of friction between the gears and thus the ability to transfer motion. The more teeth a gear has, the greater its transmission capacity.

Pressure angle

This measurement determines the angle of friction between the gears, and is greatly influenced by the number of teeth and the diameter size.

Gear module

This determines the density of teeth in the gears and is influenced by the diameter size and number of teeth.

Tooth width

This measurement determines the actual width of the teeth and is affected by the number of teeth, pressure angle, and diameter size.

The appropriate measurements should be selected for each type of gear based on the task at hand and technical requirements of the application.

This information can also be obtained from the expert team at Al Andalos Company who are skilled and experienced in providing you with the spare parts and industrial equipment that suit your needs and work requirements.

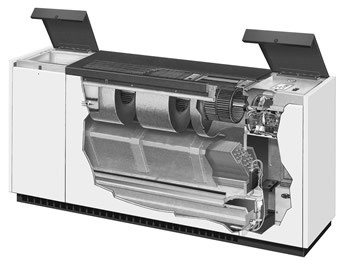

Gear movement

Refers to the movement that is transmitted from the internal gears in a gear system to the external gears or to the device connected to them.

The movement is transmitted due to the friction between the teeth on the outer surface of the gears.

Gear movement is also calculated with respect to the full rotation of each gear.

Gears can produce either rotational movement (rotation around an axis) or linear movement (straight movement in one direction).

The types of gear movement is determined based on the shape of the gears and the area of contact between them.

When multiple gears are used in a gear system, the speed ratios between the internal and external rotation of the gears can be determined.

Gear movement is also affected by the load placed on them, as the rate of movement changes based on the size of the load.

Gear movement is used in many different applications, such as motors, pumps, heavy equipment, vehicles, and other industrial equipment.

Understanding gear movement and the transmission system in machines and industrial equipment is essential knowledge for those working in the manufacturing industry, you can find all types of gears, including i-Mak gears, and other industrial equipment at Al Andalos Company.