Have you ever wondered about the number of gear motors used in the industry? Did you know how many types of gear that engineers use to operate heavy equipment and machinery? If you want to learn more about this interesting topic, keep reading to discover the most important types of gear motors and their uses in the industry.

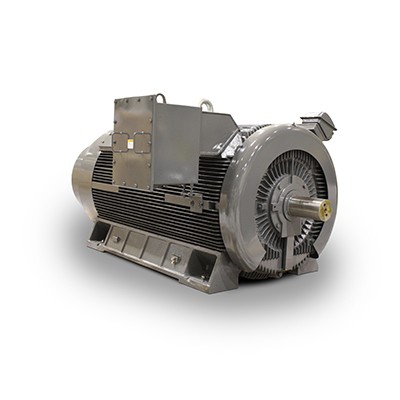

Gear motors

play an important role in controlling motion and speed when using machinery in the industry.

There are several different types of gear motors used in the industry, and they vary in their ability to withstand high pressure and vibrations.

how many types of gear used are chosen based on the nature of the work the machine will perform and the conditions it will operate under.

The efficiency and performance of the motor are also greatly influenced by the type of gears used in it.

Regardless of the type used, the length, width, height, and depth of the gears and the materials they are made of are determined according to the loads and conditions they will face during operation.

Therefore, before choosing the most suitable type of motor and gears, the operation and conditions must be studied well to ensure the best results and highest efficiency in the industrial process.

Gear Shape

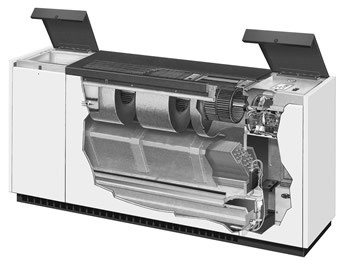

The shape of gears is what distinguishes them from other parts in machines, as machine gears are distinguished by their unique and distinct shapes.

Machine gears consist of several cylindrical or conical teeth that are connected to each other through toothed surfaces, and they move continuously at a specific rotation angle.

Machine gears are also used in a large number of different industrial machines, and their shape and size vary depending on the intended use.

The shape of the gear is determined by its intended use, and it also varies in the number of teeth, angles, and diameter.

Machine gears are essential parts that affect the efficiency and effectiveness of machines, and old gears should be replaced regularly with new ones to maintain the efficiency of the machines and make them operate perfectly.

how many types of gear

The types of machine gears depend on the type of device or machine used in the industry.

One of the common types of gears is the rotary gear, which is widely used in the automotive industry, in addition to its use in pumps, grinding machines, and forming machines.

There are also bevel gears commonly used in pumps and motors, which convert circular motion to linear motion.

There are also worm gears that are used in the transmission system and hydraulic presses, converting circular motion to linear motion more efficiently than bevel gears.

Among how many types of gear are differential gears used in the transmission system to achieve balance, and angular gears used in drilling and cutting machines.

In addition, there are multi-cylinder gears used in high-pressure pumps, which convert circular motion to high-efficiency linear motion.

In conclusion, the type of gear should be chosen according to the purpose and intended use, in accordance with the requirements of the industry, with

Andalos Company providing all industrial products and exporting them to Egypt and Arab countries.

Uses of motor gears

The use of how many types of gear in the industry dates back to an ancient time when the role of this mechanism in improving machine efficiency in the production process was discovered.

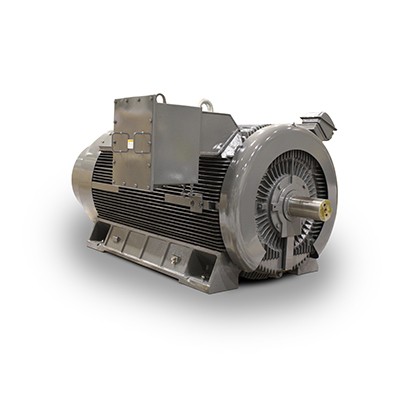

- Machine gears are widely used in the industry to increase power, improve performance speed and control heavy machinery.

- They are also used in large factories such as agricultural, chemical, electronic, and metal factories.

- There are many types of gear motors that can be used in industries that require continuous and steady work, including worm gears, spur gears, and bevel gears.

- They help improve work efficiency, reduce production time, and increase the quality of manufactured products.

- Gears can also be used in other fields such as automobiles, airplanes, boats, sports equipment, and games, where they improve performance speed and high performance in these industries.

Ultimately, the ability to use gear motors efficiently is key to success in the industry, and Al-Andalos Trading Company is one of the leading companies in supplying industrial products, how many types of gear, hold a significant position, where the company collaborates with many Turkish and international companies, including I.MAK, GAMAK, and BVN.